PPFD - 100 micromol per square meter per second ≠ 100 micromol per square meter per second

09/2017

Light for crop growing is very complex, exact and specific to each goal. This field demands patience, constant study and expertise.

Let's take a situation where two different lights are installed to light plants under the same conditions. When we put a PARMETER under the fixtures we get identical readings, however the plants react differently to each light. How does this happen? What does this mean?

The explanation may be slightly confusing and I'll try to explain the different stages.

Stage 1 - Mix

A grow light supplies a specific spectrum. A spectrum is a combination of all the wavelengths that the fixture provides and different strengths of each.

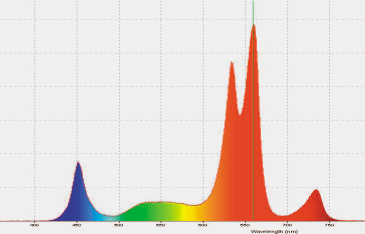

The spectrum is built by using LEDs of different wavelengths which are combined in different proportions within the fixture.

For example: We may have a linear light fixture which includes repeating groups of 6 LEDS of 660 nanometers, 3

LEDs of 630 nanometers, 4 LEDs of 450 nanometers and 2 LEDs of 730 nanometers.

The graph below shows the combination of the different LEDs. This is the Mix.

Stage 2 - Light Efficacy

Light efficacy is the parameter that describes the amount of light that the light source or fixture provides for each unit of electricity that it uses. LEDs of different wavelengths have different efficacy (PPF/W).The light efficacy is dependent on wavelength, type of LED, series of LED and manufacturer. For example, in the PFL series that we offer, there is a 660 nanometer LED with light efficacy of 2.78 micromol per second for each watt of electricity and a 450 nanometer LED, from the same manufacturer, with a light efficacy of 1.83 micromol per second for each watt of electricity.

Stage 3 - Measurement

A PARMETER, which measure light strength, gives us one value, the PPFD - the photon density at the point of measurement.

Not all measuring instruments break down the spectrum and tell us how much PPFD we have from each wavelength. In many devices we get a reading of the intensity of the light fixture and its spectrum together.

Stage 4 - Simulation

If we take a light fixture with LEDs of 450 nanometers from the example in stage 2 and we use of number of LEDs necessary to give a reading of 100 micromol per second at a distance of 40 cm., then we take another fixture with LEDs of 630 nanometers from the example, we will need fewer LEDs to reach the same 100 micromol per second. The electric usage will be lower in the second fixture but the photon density will be the same.

What is definite is that the plant will not react the same way to the two fixtures, even though the photon density reading is identical.

From this, we understand that when we measure PPFD, the result is a certain Mix of LEDs with different light efficacies.

There is no point in just measuring PPFD alone. The photon density must be checked across the spectrum.

Stage 5 - What the plant wants

Each plant demands a certain photon density in a certain spectrum. This combination complicates things. Worldwide, plant research, experimentation and species development is being done on this subject. A head of lettuce, that we don't want to flower, needs a different spectrum from a strawberry plant that we want to fruit.

Now, what do I want to say?

ANY GROWER, ENTREPRENEUR, MANUFACTURER OR SUPPLIER WHO CHOOSES TO USE LEDS FOR GROWING NEEDS TO UNDERSTAND AND ASPIRE TO DEFINE THE PHOTON DENSITY REQUIRED TO ACHIEVE THE WANTED RESULT FROM THE PLANT.

Using photon density alone will not produce an effective result. The expertise and challenge is to define photon density in the specific spectrum, with a Mix of the specific wavelengths, which will then produce the optimum result in each plant. When we can accurately and reliably define each of these points, then we can grow and produce exactly what we want. The crop will reach the size, weight, color, taste, growth period and shelf life that the customer wants.

Lighting is a critical component in the success of INDOOR farming

It is the most expensive part of the whole system necessary for growing crops in this type of facility. Don’t compromise; experiment, compare options and work with a manufacturer or supplier who understands the language and the field. Only these suppliers will know how to advise, recommend and offer solutions for your needs.